In attendance: Andrew, Kiah (until the vaccuum pump scared her away)

I sucked really, really hard on foam tonight, to see what would happen.

Pre-sucking:

I took two ~6 inch pieces of 1/16 inch thick polyethylene foam tape and stuck them back to back to make 1/8 inch thick tape. I left the laminated plastic tape on the outsides so it wouldn't stick to the calipers and bell jar. I measured across the tape with the calipers and got:

| Original 6 inch double-thickness tape | 0.110 +/- 0.001 inches |

Sucking

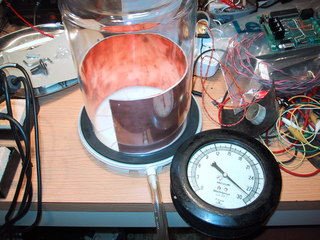

I set up my old 1950's (?) vacuum pump (to which I'd many, many years ago added a 1/4 HP motor and belt) complete with an insanely innacurate vaccum gauge and polycarbonate bell jar.

You better beleive I wore eye protection. I was cringing the whole time during these tests, just waiting for something to implode.

So then I sucked on the foam strip. Down to > 29 in Hg according to the gauge. I left it pumping for two minutes, then turned off the pump and let it sit in the bell jar. As far as I could tell, the tape strip never moved, unbent, or anything during the entire process. It just sat there.

So I cut the vacuum in about 5 seconds, pulled the bell jar off, and quickly measured it again:

| Thickness of tape after 3 minutes in 30 inches Hg vaccuum | 0.110 +/- 0.001 inches |

Didn't change a bit. I repeated this whole process again, with the same results.

Prototype Sucking

Then I put the original CPA prototype (full copper PCB, tape, ground plane, even a prototype pigtail) in the bell jar to see what would happen. As the vacuum started sucking, the entire prototype unfurled until it hit the bell jar walls (which was only about 0.5 - 1 inch difference in radius). It was stable after that for the 2 minutes I left it in the bell jar. Upon releasing the vacuum, the prototype collapsed back to its original shape. I think air trapped between the strips of PE tape made it expand and collapse. I don't think it involved a lot of force: even when the vacuum was suddenly released, the patch antenna curled back up relatively slowly.

In-situ Sucking

I really wanted to know if the foam expanded at all in a vacuum. So I put my calipers in the bell jar and gave it a try. I figured that if it really expanded, the pressure of the foam on the calipers should push the jaws of the calipers apart. The initial measurement was:

| Tape after body weight crush | 0.109 +/- 0.001 inches |

Note that the 0.001 can be explained by the fact that I accidentally sat on the tape while writing up these notes.

| 30 inches Hg, calipers upside down | 0.1470 inches |

Very interesting. After releasing the vacuum, the foam shrunk back to it's old self:

| After body weight crush and after vacuum | 0.110 +/- 0.001 |

I tried it once more, this time with the calipers right side up so the weight of the head woudldn't be pressing on the foam, and I only took it to 15 in Hg - what we discussed might be the pressure at 30,000ft. The foam expanded to:

| 15 inches Hg, calipers right side up | 0.1440 inches |

But I forgot to take it all the way to a full vacuum. So I ran it once more, with the calipers right side up like before:

| 15 inches Hg, calipers right side up | 0.1410 inches |

| 30 inches Hg, calipers right side up | 0.1485 inches |

Conclusions

- 3m #4466 1/16 inch thick polyethylene foam expands it's thickness in a vacuum by ~35%, and at a half vacuum by ~27%. According to Tim's sensitivity analysis of the thickness vs resonant frequency, this means a resonant frequency shift of approximately -3.7 MHz and -3.0 MHz respectively.

- The foam recovers its original thickness under normal pressures.

- Our CPA design may experience internal pressures due to air caught inbetween the foam tape strips.

- Dogs hate vacuum pumps.