What explains the thickness differences?

There is a considerable thickness difference between the cylindrical patch antennas (CPAs) and the flat cylindrical patch antennas (FCPAs). It comes out to about a ~5 MHz difference in frequency, which is of borderline importance. But we think it's important to account for these things.

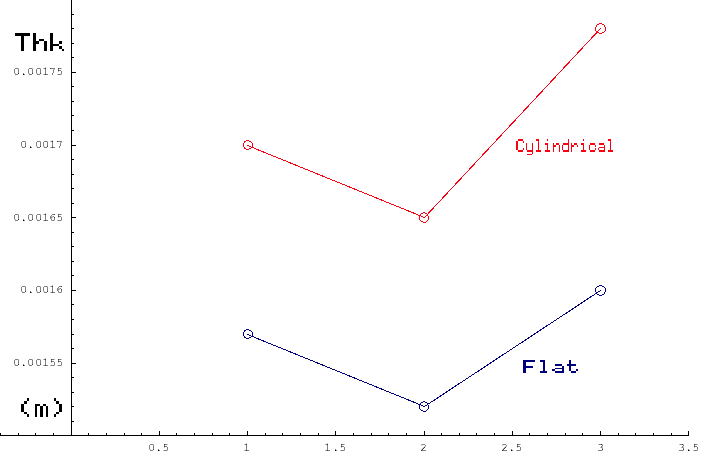

The above graph shows the thickness of the foam dielectric for the first six test antennas, measured with great care with digital calipers. The thickness is in meters. The red portion is the thickness of the cylindrical antennae, the blue shows the flat antennae. The horizontal axis is arbitrary, but it is in order of increasing operating frequency. "1" marks the ATV antennae, "2" the GPS, and "3" the WiFi antennae. The connecting lines have been drawn to emphasize the correlation between the cylindrical and flat antenna thicknesses.

The existence of this correlation is, at present, unexplained.

We at first thought the order of antenna manufacturing would tell us something, but it doesn't that we can see:

Build Order: (Cylindricals built at black rock, flats in Portland)

- Cylindrical WiFi

- Cylindrical GPS

- Cylindrical ATV

- Flat WiFi

- Flat GPS

- Flat ATV

So we hypothesized reasons for thickness difference:

- Air pressure

- Thickness of tape given beginning/middle/end of roll

- Bunches as it goes around a curved surface

- Crinkles as the wound tape is put flat

- Temperature

We think that the pressure really might make a difference - all the CPA's built in the BRD (5,000 ft) were slightly thicker than the flats built in my basement.

Here's our explanation (Some of the data for this calculation comes from our foam-sucking experiments page.)

Based on our foam-sucking experiments, The foam tape expands easily in a weak vacuum, but reaches a maximum expansion of about 34% under full vacuum.

We can interpolate the expansion at 5000' from the foam-sucking data.

- delta-thickness/delta-pressure = (x1-x2)/(P1-P2)

- = (2.70 mm - 3.49 mm) / (101325 Pa - 50662.5 Pa)

- = -15.6 nm/Pa

At 5000' the standard pressure is 84307 Pa . The relative change is:

- (2.70 mm - 15.6 nm/Pa * (84307 Pa - 101325 Pa))/(2.70 mm)

- = +9.8%

From our graph above, the average change from the flat to cylindrical antennas is +9.4%, which is entirely consistent with the foam-sucking data.

We think that there might be linear change in the thickness of the tape between the beginning of the tape roll and the end, but this can't explain our non-monotonic results. At this point we just don't know.

What Next

We decided to build 1 or 2 more CPAs in Portland, near sea level, as soon as we could. Also, we want to try the eyelet technology to make sure that's viable for the v3 design. So here's the current timeline:

- Andrew preps the remaining v2 antennas and copper ground plane, and purchases new foam at RS Hughes. Possibly very wide foam.

- Tim gets eyelet technology.

- Tim and Andrew meet Friday morning to build the antennas with the eyelets: they record the temperature and pressure.

- We deliver the antenna(s) to Glenn Friday and he tests them on the VNA for resonant frequency and bandwidth that weekend: Saturday, Sunday or Monday.

- Tim and Andrew take the results, and if they're vaguely consistent, finally finish the v3 design. If they're really off, then we panic and call a meeting.