Hybrid Meeting Minutes 07/23/05

In attendance: Brian O’Neel, Evan Waymire

Topics Discussed:

Gox/Paraffin Work:

Over the past few weeks the version 2 motor has been moving forware (Thanks Maggie!). We now have one complete set of  minus the snap ring grooves. Evan finished the snap ring analysis and whipped out an improvised snap ring cutter from a tool steel blank. We will try to get the grooves cut this week and fully assemble one motor.

minus the snap ring grooves. Evan finished the snap ring analysis and whipped out an improvised snap ring cutter from a tool steel blank. We will try to get the grooves cut this week and fully assemble one motor.

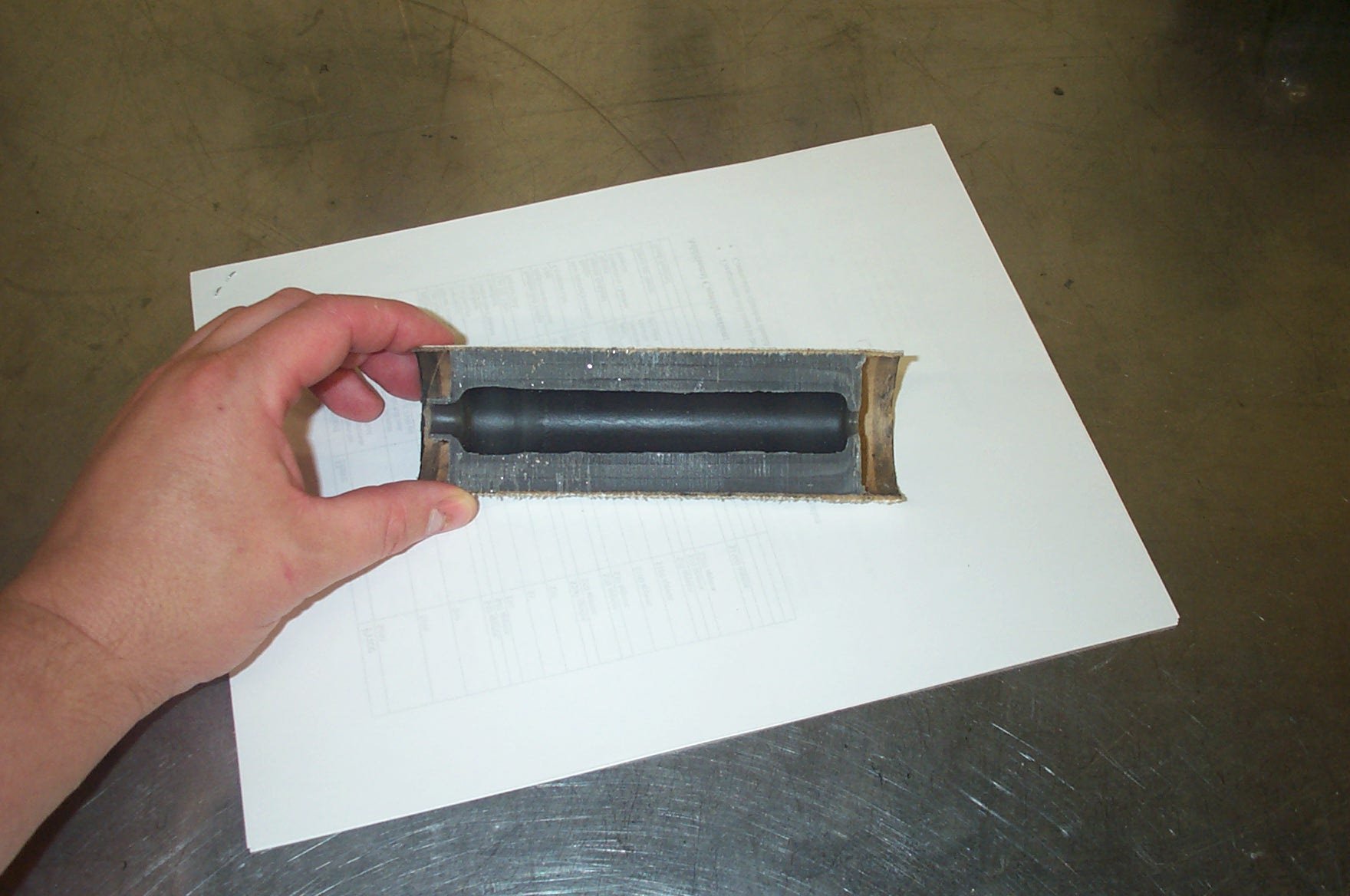

The new spin casting technique is also a success. We will be able to try the  in the version 2 motor as well. The new technique uses the lathe to spin the grain, while molten paraffin is introduced through a hole at one end of the spinning assembly. The end cracking and surface cracking issues we have seen in the past are now resolved.

in the version 2 motor as well. The new technique uses the lathe to spin the grain, while molten paraffin is introduced through a hole at one end of the spinning assembly. The end cracking and surface cracking issues we have seen in the past are now resolved.

The Matlab 'hybrid motor' code is mostly done. The program will perform a quick and thorough analysis of the motor performance from the Excel spread sheet created by the Lab VIEW DAQ system. Some tweaks and clean-up are still needed and the GUI front end needs to be finished. It should all be done in the next two weeks.

Everything is on schedule to do a static test fire of the new motor sometime after the upcoming LV2 launch in August. The only major hurdle is still the regression rate sensor. This is an area that we really need to focus on since we will not be able to accurately quantify the burn rate of the paraffin without it.

Lox/Paraffin Work:

In parallel with the gox work we are starting to discuss the Lox/Paraffin hybrid more. This is the right time to be doing research on alternative designs and perhaps prototyping some proof of concept experiments. Most of the discussion at this point is centering on the different possible lox feed schemes to deliver the oxidizer into the combustion chamber. Among the ideas are self-pressurized, externally pressurize, and pumped (by various means). Brian presented an outline for a 3 phase plan to build a pressure fed system in two years time. A 'phase one' proof of concept system will be built to evaluate this system over the next few months using  that we have around.

that we have around.

Much more discussion, research, and evaluation need to occur in areas such as:

- Feed Systems

- Valves, Rupture Disks, and Solenoids

- Tanks

- Injection

- Plumbing Connection Methods

- Ignition Techniques

- Nozzle Material (i.e. graphite grades)

- Sequencing

- Active Control

In summary, there is still a huge amount of work to do on the lox design and a smaller amount to still do on the gox hybrid. The gox hybrid work needs to be completed in order to have a satisfactory motor capable of the target 50lbf and fully sensored. Then we can start doing some real number crunching :)

Things that still need to be done on the gox hybrid:

- Regression rate sensor

- Analysis of Hemholtz method for measuring regression

- Build test stand adapter for version 2 combustion chamber

- Gang together both oxygen tanks

- Finish Matlab analysis software

Our next propulsion meeting will probably be September 3rd, due to scheduled pre-launch test for LV2 during the upcoming weekends.

There will still be flexible weekly work parties at the shop if you’re interested in contributing. The work sessions are fairly short (3hrs) and are focused on completing specific tasks and not so much focused on discussing design philosophy. So if you feel like getting your hands dirty please send an email to either the propulsion mailing list or 'oneelb@postmark.net'