Hybrid Meeting Minutes 05/15/04

In attendance: Rainer Anacker, Peter Bold, Eric Hettinger, Brian O’Neel, Michael Pence, Jim Ward, Evan Waymire

What we did today:

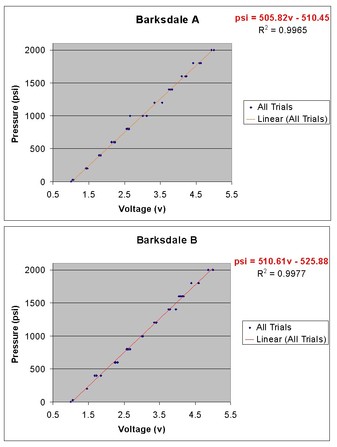

We got the dead weight tester running and were able to get calibration curves for both of the Barksdale 4-20 mA output pressure transducers. Both sensors behave linearly and have good repeatability. We were unable to test for hysteresis due to the nature of how the dead weight tester operates.

A schematic of the signal conditioning can be found here. The code we used to capture the data can be found here.

With this information we will now be able to write a program in Labview that will allow us to monitor the upstream pressure relative the metering orifice and also the downstream pressure. Knowing these two values we will be able to verify that we are maintaining choked flow at the metering orifice thereby insuring a known volumetric flow rate into the combustion chamber.

The Labview program will take the sensed voltages from the transducers and apply it as a variable into a ‘formula node’ that contains the equation for the straight-line curve fit for the sensors that we generated today. The output for the ‘formula node’ will give us our upstream and downstream pressures that we can display use to manipulate the regulator setting in the future.

Jim brought his LabJack data acquisition system online and running under Labview 7.0. This is a cheaper alternative to the PCI-1200 card and is easily plugged into a USB port. Though its sampling rate is less than the PCI-1200 (8Ks/S vs. 100Ks/S) it is much less expensive (approx. $120) and is far more convenient. It comes with drivers that will work under Labview 7.0 where the PCI-1200 will only work with Labview 6.1. A student version of Labview 7.0 can be purchased with manual for about $75. So for less than $200 a very powerful data acquisition and control system can be had. We will probably use both systems in the near term to give us both high sampling rates, when needed, and portability.

We discussed and developed our idea to discretely measure regression rate inside the motor by weaving a web off precisely spaced closed circuit wire loops and monitoring them during motor burn to see the time interval between loop openings due to the wires melting through. This does not seem like an ideal way to measure regression rate but it appears to be the least expensive and most realistic method that can be employed in a short time. Rainer brought over some very fine coaxial wire that might be idea for doing this.

Things we learned today:

We had to make many modifications to the dead weight tester in order to adapt it to the ¼” NPT thread on the transducers. It’s important to make sure all the connections are Teflon taped and well sealed. At 2000 psi even a small leak will register as a dropping pressure.

Slightly Damaged O-rings on a dead weight tester will cause it to not function correctly.

Replacement of the hydraulic oil with distilled water in the dead weight tester might be the possible cause of some minor piston sticking.

The switching power supply we were originally going to use to power the pressure transducer was too noisy. It could not easily be filtered so we temporarily switched to an adjustable linear power supply that works, but just barely has the required output. In the future we may just use a 24VDC battery supply.

The Barksdale transducers say they will operate with an input voltage between 12-47VDC but ours seemed to need a minimum of 15VDC to operate anything less and the transducer could not regulate the current output and it floated around 20mA with no load on the transducer.

Occasionally when in operation with 16VDC input voltage the output would remain at 20mA after a full scale deflection to 2000psi and not drop back down. When the input voltage was removed and the transducer input terminal shorted together the transducer would reset.

What’s Next:

We will meet again in two weeks and pour a new batch of paraffin fuel grain. And hopefully make some progress on the new load cell and new test fire coding.

Action Items:

Peter Bold:

regulator power drive possibilities.

Eric Hettinger

Keep looking for an inexpensive load cell.

Brian O’Neel:

New test stand.

Regression rate wire web.

Jim Ward:

Labview 7.0 and Labjack interfacing

Evan Waymire

work out leak issues in DWT.

Of Interest:

Paraffin article from "Graduating Engineer & Computer Careers"

Attachments: