Who: Andrew

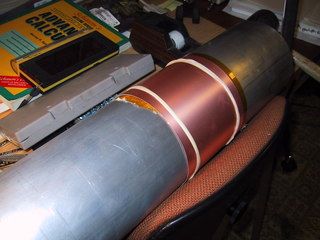

I tried mocking up a CPA with the new materials tonight.

The idea:

Outer surface: 0.005 in. thick "epoxy glass board". When measued with a calipers, it was 0.0055 in. thick, 0.5 oz copper. We'll etch the "inside" part of the board with the patch, so that the fiberglass backing protects it.

Dielectric: ~1/16 (0.0625) in. expanded (in place) polyurethane foam.

Inner surface: 0.010 in. thick copper sheet. Maybe use another piece of PCB material?

I had a polyethylene mold made out of two pieces of 1/2 in. thick polyethylene sheets. Even though they were thick, one was still clearly bent! Unbelievable.

Ground plane length on 5.25" airframe tube:

inner: 16.49336143

outer: 16.52477736

diff: 0.03141592

So I chose to make it slightly more than 16.5".

Radiator length on 5.25" airframe tube, and in 0.074" mold:

inner: 16.70856053

outer: 16.72583929

diff: 0.01727876

So I tried to make it about 16 23/32".

Width of patch and ground plane:

In terms of thickness: cpa_calculator_3.xls calculated a 2.422GHz, Er = 1.3 antenna patch to have a patch width (length, really) of 2.1370 in. Given the rule of thumb of 5x the dielectric thickness from any driven surface: (0.074 - 0.01 - 0.0055) * 5 = 0.292 in.

So:

spacing + patch + spacing + spacing + level 1 of corporate feed + spacing + spacing _ level 2 of corporate feed + spacing = 0.292 + 2.137 + 0.292 + 0.292 + 0.1929 (w_Zin) + 0.292 + 0.292 + 0.3134 + 0.292 = 4.3953 in

So I rounded it to 4.5".

Try number 1: Make yourself an antenna

- 0.010" copper foil is way, way too thick to cut with a razor blade.

- 0.005" 1/2oz double sided PCB is incredibly easy to cut with a razor blad.

Don't tape BOTH sides down well. Duh.

Pour A first. DO NOT MIX UP THE CAPS. Clean up the cap of "A" VERY, VERY WELL.

- There is only about 10 seconds of mixing time, MAX, before you HAVE to pour it, otherwise it's too goopy to drop down to the bottom of the mold.

- I used 1/2 oz A + 1/2 oz B and it was too little. It really should "pour" over the top so that we know it's reached all of the places in the mold.

- After about 10 minutes, it's completely skinned over.

Try Number 2: Screw the antenna, settle for the dielectric

- 1 oz + 1 oz seems just right. Next time, use 1.25 just to be safe.

- Measure out the quantities first, then pour into a larger cup.

- Use a cut-up straw w/a drill to mix. It's SO much better. And faster.

- BE SURE TO CLAMP THE MOLD AT THE TWO MIDDLE POINTS ON TOP!

AAAARRRRGGGHHHHH. The EPU Sticks to the polyethylene.

Try Number 3: new mold technique

Garbage bags work great. Make metal mold, cover with garbage bags.

Update 2003/11/10: EPU didn't work since it expands too much after it dries. We've since moved to 1/16 inch double-sticky polyethylene foam tape.