Who: Andrew

We'd like to use EPU as the dielectric for our cylindrical patch antennas. We think since it's pretty much air it'll have a low dielectric constant - say 1.01 - 1.2 or something like that. So we did some tests to see how it behaves.

It's a 1:1 mix, and in my basement (~75 degrees on a hot sunny day) here's what happened:

| Time | State |

|---|---|

| 0 - 10 s | Thick but very pourable amber liquid - think hot maple syrup. On contact, the two chemicals begin to produce microbubbles which turns it a yellowy tan. |

| 10 - 20 s | The mix changes from a liquid to a still-pourable foam. It's starting to thicken up. |

| 20 - 30 s | Now the mix is really foammy, and getting harder to pour |

| 30 - 60 s | The foam turns into a sticky mess - it can slowly drip, but even that stops after a while. If you cut it with a knife, the edges peel back like the "7-up jello mold" my grandmother used to make us... if we were good. |

| 60 - 600 s | The foam moves from squishy and cutable to soft but firm. Then it really firms up, and for a while acts like that closed-cell polyurethane packaging foam - stiff but bendy. |

| > 1 hr | It gets progressively stiffer until about 2-3 hours after you start, it's a very brittle, stiff foam. |

First we just mixed some stuff up. It stuck to glass, ABS and styrene plastic.. it's nasty stuff to take off, too. Acetone doesn't touch it.

Second we made a polyethylene mold out of a 6 x 6 x 1/8 in piece of polyethylene with three 6 x 0.5 x 1/8 in strips. This worked very well; it stuck to the polyethylene but not badly so - a little bit of bending the mold and peeling took it out just fine. So we got our first piece of 5 x 5 x 1/8 in EPU successfully. Fun. We tested one of the pieces for density and found it to be 31.7 mg/cm^3, which is 1.97 lb/ft^3: very, very close to the 2 lb/ft^3 specification.

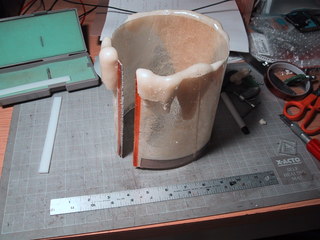

Just for fun, we decided to try making a cylindrical mold which was roughly the right size for LV2 (5.25 in. OD airframe). We used the only available material, 1/32 in. thick clear polycarbonate (Lexan), and cut it into two 6 in. wide sheets, one 16.75 in. long and one ~ 16.31 in long. We rolled them up, taped the edges together with Kapton tape (what else would look as cool, really?) and then slipped them inside each other. We inserted a strip of 1/16 in. thick protoboard to seperate the cylinders and then clamped the interface with the polyethylene sticks and some C clamps. It was a bit of a challenge to pour the foamy liquid into the 1/16 in. spacing, so we just used a stick to open up the gap near where we were pouring the foam. It actually worked quite well, considering - if we had had a funnel with a <= 1/8 in. tube I think it would have been very easy (and not so messy!).

Note the closeup of the bubbles - this stuff is very low density foam. After about 15 hours, we unclamped it and cut the Kapton tape. With a bit of coaxing, it opened along the split and stood about 1" open. That's pretty impressive given that the polycarbonate sheets had quite a bit of springyness to them... the foam did a nice job of keepin it in a cylindrical shape.

I played with it for quite a while, flexing it open and closed, torquing it this way and that. It was pretty hardy, but the occasional "crack" noise meant that stuff was breaking.

I then really flexed it open, and got the first visible failure. The foam broke right down the center between the two sheets of polycarbonate - i.e. delaminated. Not surprisingly, it separated at the only section that didn't have a thick layer of foam on top. If we could seal the edges with a stiff but rubber glue, like a silicone rubber, I think it would have done better - still cracked, though.

Finally I peel tested the edge. It had a good peel strength (sort of surprising, actually). The EPU broke down the center of the thickness and came right off the polycarbonate in an equal amount.

Conclusion: It just might work. It's a little more brittle than we want, but if we don't over-flex it we'll be fine. it would be nice to have something more plyable, like a polyethylene or polypropylene, but this stuff will do. Note that we could actually save ourselves quite a bit of hassle by making a a straight, thick-walled polyethylene mold, and then removing the EPU from the mold after about 20 minutes, before it's fully cured. It would easily wrap around a 5" cylinder at that point, so it would save us the headache of making a cylindrical mold.

Update 2003/11/10: EPU didn't work since it expands too much after it dries. We've since moved to 1/16 inch double-sticky polyethylene foam tape.