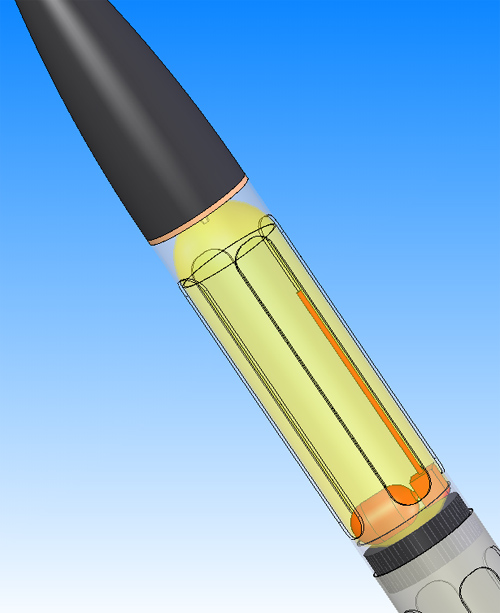

Nosecone Separation Design

The current nosecone separation system design will consist of a gas-tight parachute container and a conventionally sleeved nosecone. A cold gas generator could be located below the parachutes, which simplifies the wiring, plumbing, and nosecone interface considerably. A cold gas generator could be purchased from a third party such as Aerocon. http://www.aeroconsystems.com/RTM/index.htm A sample model drawn in solidworks is shown below.

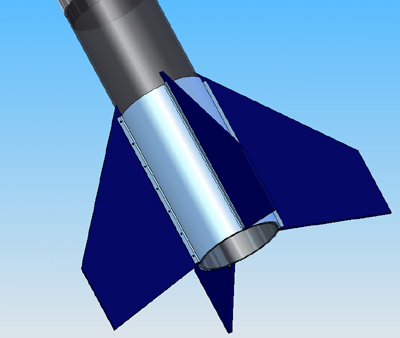

Fin Design

The current fin design involves clamping four fins equally spaced at the bottom of the propulsion module. By tightening the fasteners on each fin, a compression fit is obtained.A sample model drawn in solidworks is shown below.

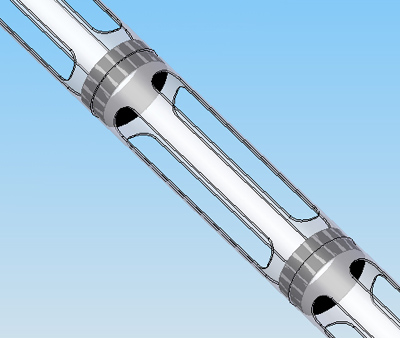

Module Coupling Design

The module coupling design consists of a coupler, roughly 2 inches in length, tightly fitting within the ends of the modules. A series of fasteners will sufficiently attach the coupler to the module. A sample model drawn in solidworks is shown below.

Materials

Materials for the Aeroshell:

- Class C fiber glass

- Mylar

- 5 mil plastic paint tarp

- Weather stripping

- Epoxy

- Pigment

- Aerospace Composite Products Pigment Paste ($6.00/2oz)

- Perforated plastic sheets

- Aerospace Composite Products Perforated Release Film ($6/yard) http://www.acp-composites.com/ACP-CAT.HTM 800-811-2009

- Sand paper

- Paint

- Bolts for attaching to modules

Major Airframe components: (excludes parachute and related hardware)

- Aeroshell

- 18" long fiberglass tubes ~5" I.D. ~1/16" wall

- Nosecone

- Also fiberglass layup

- Nosecone separation system

- No viable plan yet

- Modules

- Aluminum tubing ~5" O.D. 1/8" wall

- Module couplers

- Nesting aluminum tubing sections. Possibly minimum length (~2")

- Launch lugs

- UHMW PE bobbins, assuming the launch rail system is the same.

- Fins

- Fiberglass with four aluminum wrap-around clamps securing them.